1.Control cable:

Insulation electric strength: 1min 1kv between conductors without breakdown, conductor and shield 1min 3kv without breakdown;

Insulation resistance: each core wire is grounded with other cores, the control cable is greater than 10000MΩ.km, and the HYAT cable is greater than 3000MΩ.km.

2.Signal cable:

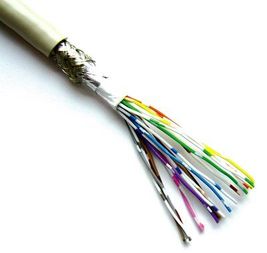

Generally, the signal transmitted by the signal cable is very small. In order to prevent the signal from being interfered, there is a shielding layer outside the signal cable, which is the shielding layer of the wrapped conductor.

Generally, it is conductive cloth, braided copper mesh or copper foil (aluminum), and the shielding layer needs to be grounded. External interference signals can be guided into the ground by this layer, preventing interference signals from entering the inner conductor and reducing the loss of transmission signals.

Different uses of cables

1.Control cable:

It is suitable for PVC insulated and PVC sheathed control cables used in industrial and mining enterprises, energy and transportation departments, and for control and protection lines with AC rated voltage below 450/750 volts.

2.Signal cable:

The sensor signal cable is used for signal transmission of various sensors and instruments; the sensor signal cable adopts silver-plated conductor and multi-core structure. Ensure that the resistance between each core is highly consistent, and the weak power signal can be accurately transmitted hundreds of meters away.

Different cable materials

1.Control cable:

The wire core is copper core, with a nominal cross-section of 2.5mm2 and below, 2 to 61 cores; 4 to 6mm2, 2 to 14 cores; 10mm2, 2 to 10 cores.

Working temperature of control cable: 65°C for rubber insulation, 70°C and 105°C for PVC insulation.

The control cables used in computer systems generally use polyvinyl chloride, polyethylene, cross-linked polyethylene and fluoroplastic insulation products.

2.Signal cable:

On the one hand, exquisite metal materials must smoothly lead out interference signals, and the extremely thin metal wires must have sufficient bending resistance to prevent metal debris from affecting other electrical equipment.